High-Level and Design Considerations

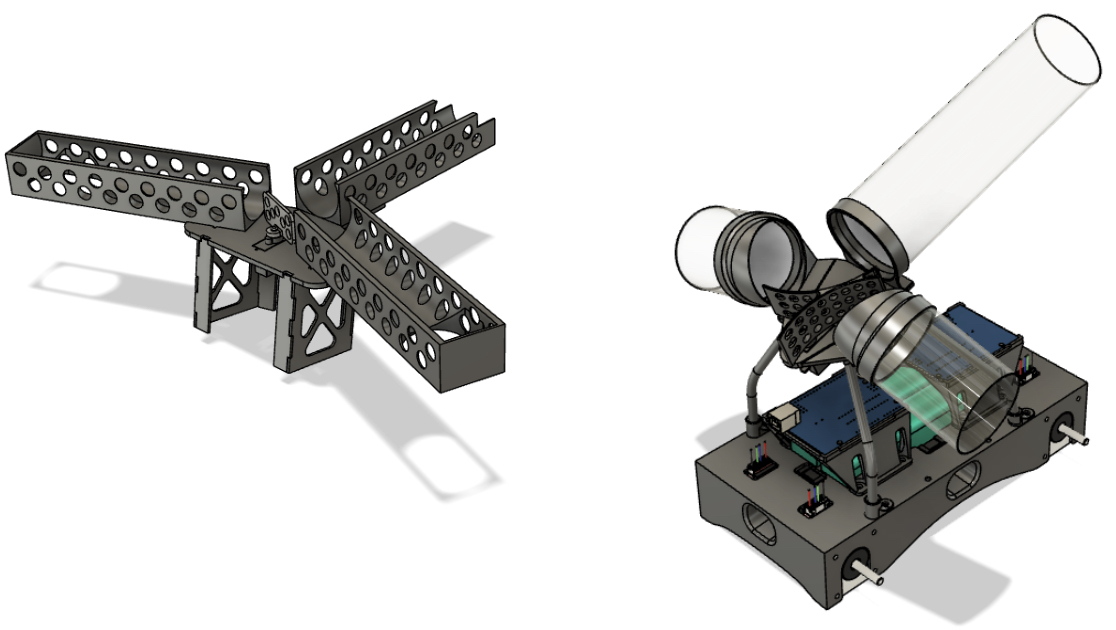

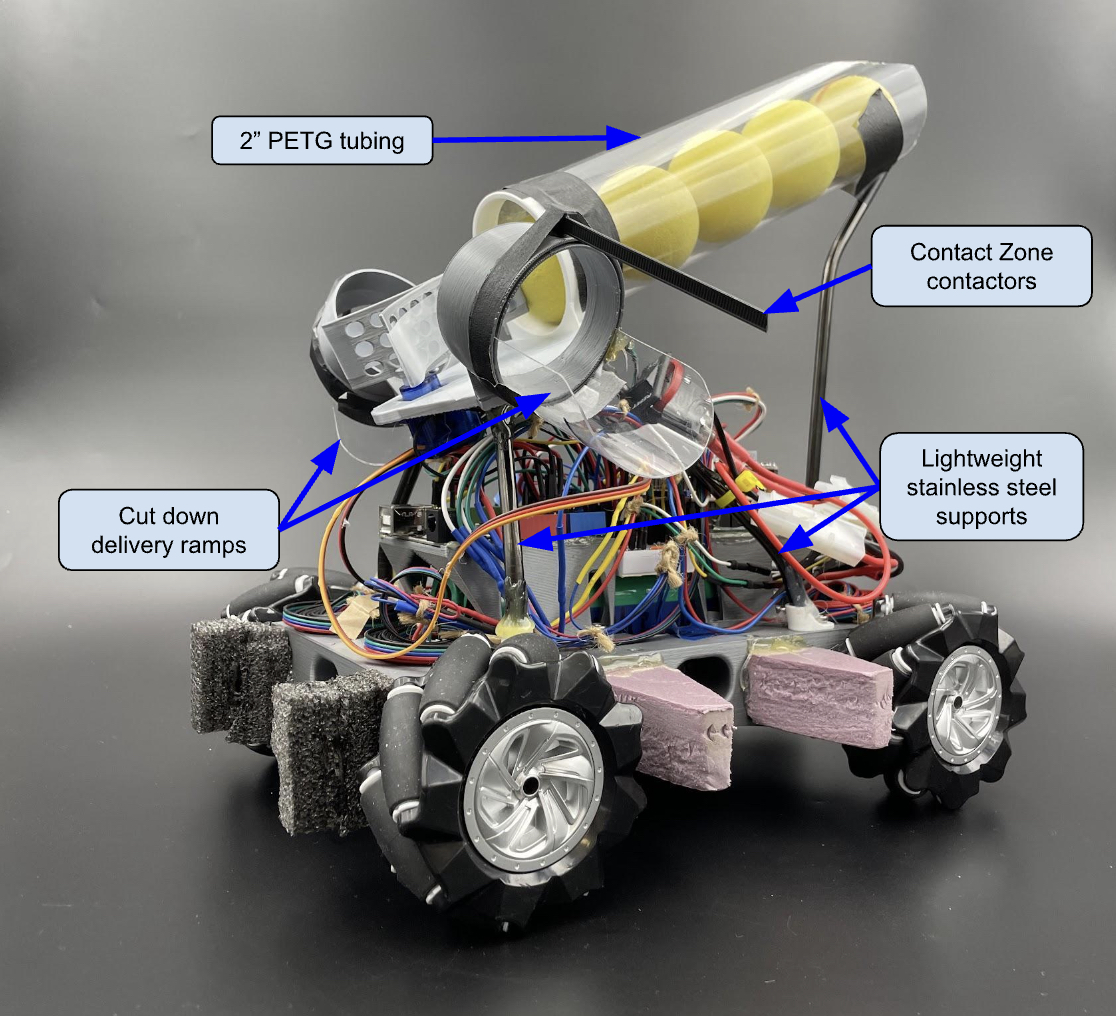

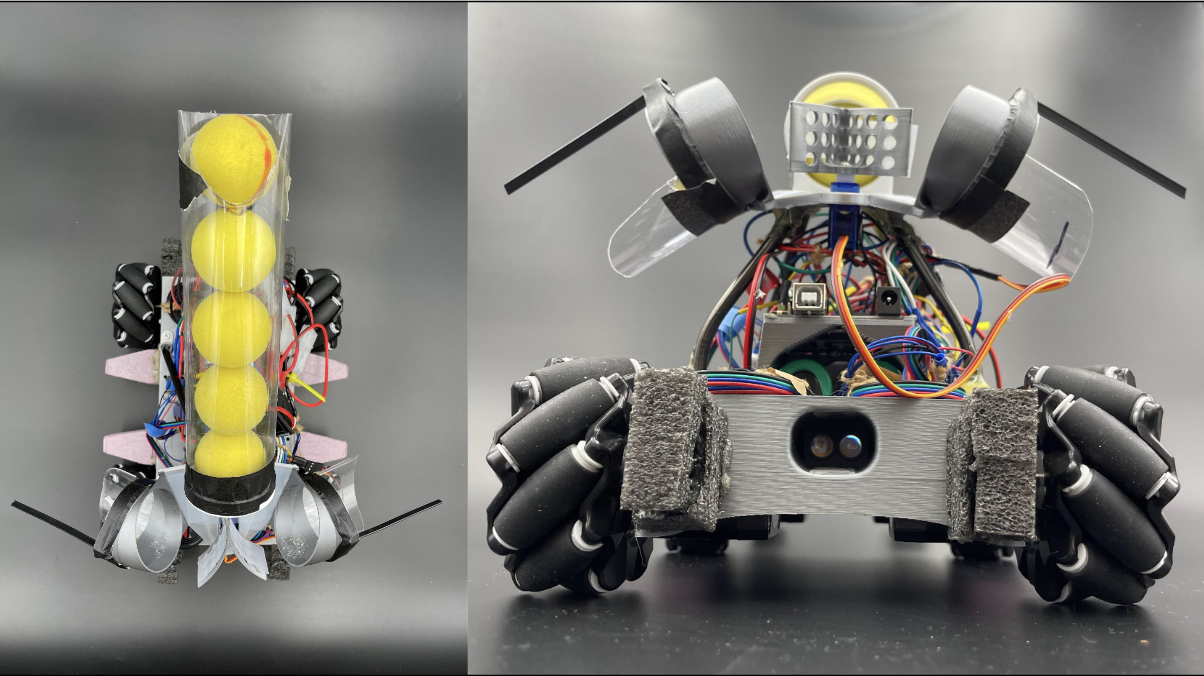

Our primary objective for the payload delivery system was to minimize or eliminate the need to orient the platform. Our final design captures this in a simple, yet effective form. Constructed from stainless steel struts, PETG tubing, and 3d printed components, the centralized hopper and curved side-selector allow for deployment to the left or right without the need to reorient -- all controlled by a single servo.

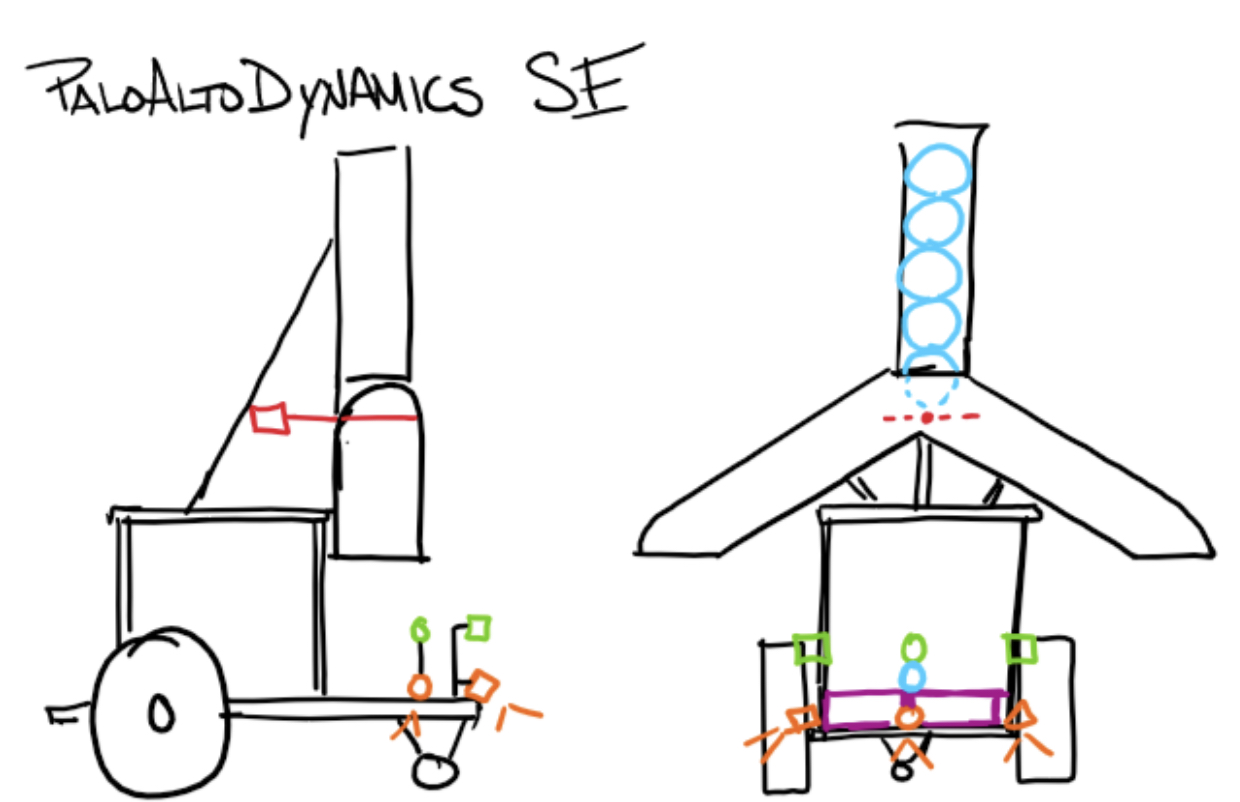

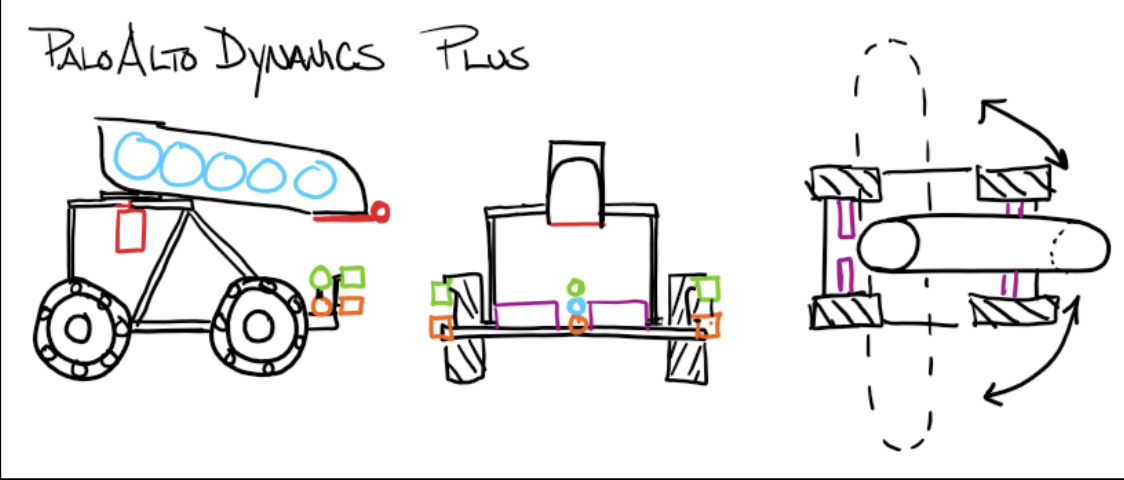

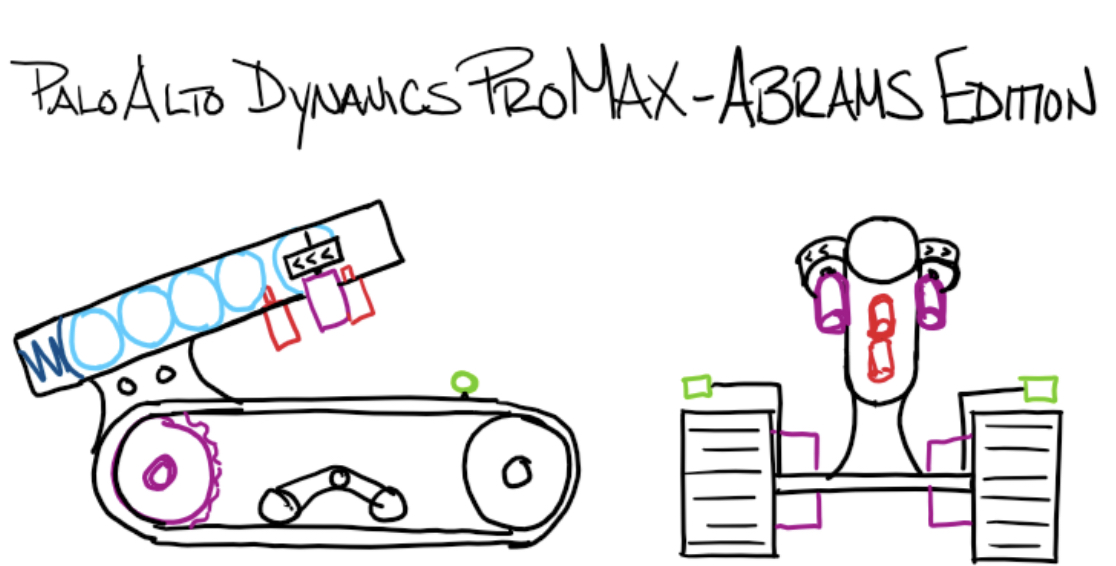

Design Evolution

Design Evolution

Early designs were based on a fully 3d printed construction. However, the size, mass, and print times proved impractical so other options were sought. We sourced inexpensive 2” diameter tubing to serve as the hopper and delivery chutes, and only used 3d printed parts for the connections.

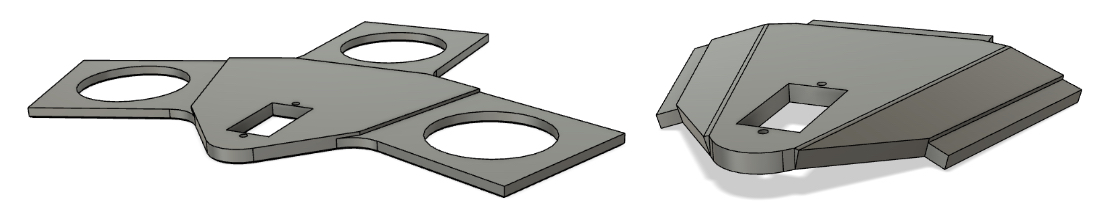

Mounting Plate

The first design for the mount which connects and supports the tubes was unreliable. So, we redesigned the parts to make the deployment angles more aggressive, which improved offloads.

The final mounting plate, shown on the right, included improvements in weight and size, and added a slope to the delivery chute mounts to improve offload consistency from earlier designs (left).

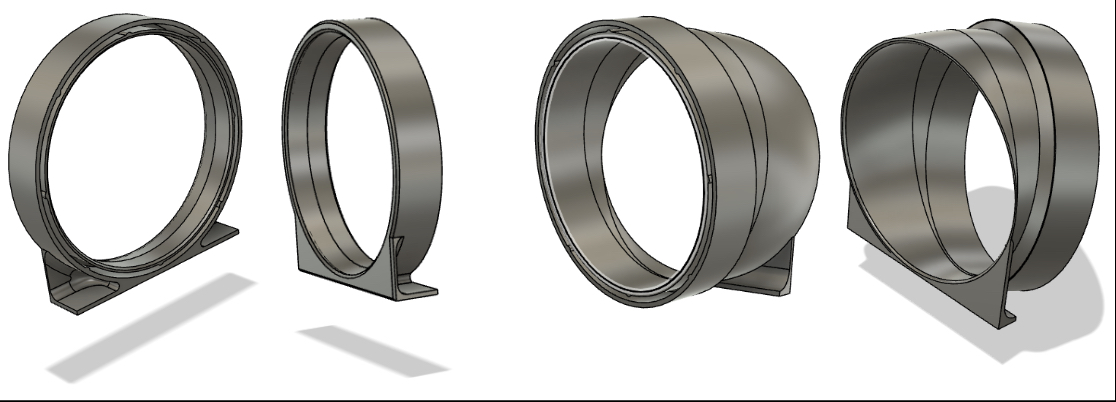

Tube Supports

Tube supports evolved to include a 20 degree backward sweep, and a 10 degree downward sweep to align balls with the center of the basket.

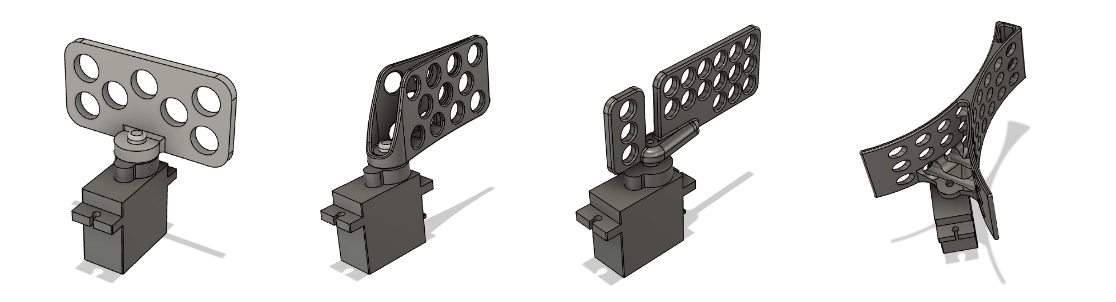

Side-Selector

The selector proved to be a considerable design challenge. The textured surface of the balls has a very high coefficient of friction, so the balls would jam in the chutes. The horizontal design, shown on the left side of the image below, did not allow the balls to fall far enough to develop the energy necessary to overcome that friction force. To correct this, we designed a vertically oriented selector which held the balls higher, allowing them to fall farther before being directed left or right. Then, we adapted the design to provide the smoothest transition from the hopper to the deployment chute, eventually landing on the design seen on the right side of the image below.

The horizontal model did not allow ball to accelerate enough to overcome the friction of the ball’s suede-like texture. The final version has a radius that matches the curve between the hopper and the delivery chute.

Controls

The payload deployment system is controlled by a single servo. While it is a simple operation, two issues arose during testing.

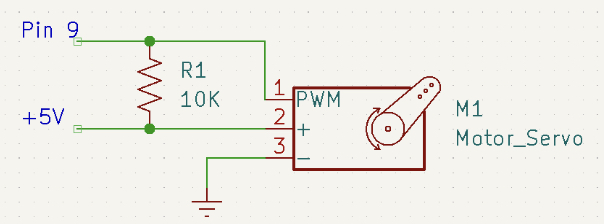

Problem 1: Servo Oscillation

Because the servo is powered directly from our 5V DC bus, it powers on before the Arduino Uno used to control its PWM inputs. This meant that when the bot was powered on, the servo would oscillate until the Arduino powered on and fixed its position, sometimes up to 20°. This would often cause the selector to jam against the first ball, preventing deployment, and stressing the servo.

Apparently, this is a common problem, and research pointed us to a quick solution. By adding a 10K ohm resistor between the PWM and the +5V connectors, the servo position is essentially fixed during power up, correcting the problem. A diagram of the solution is shown below.

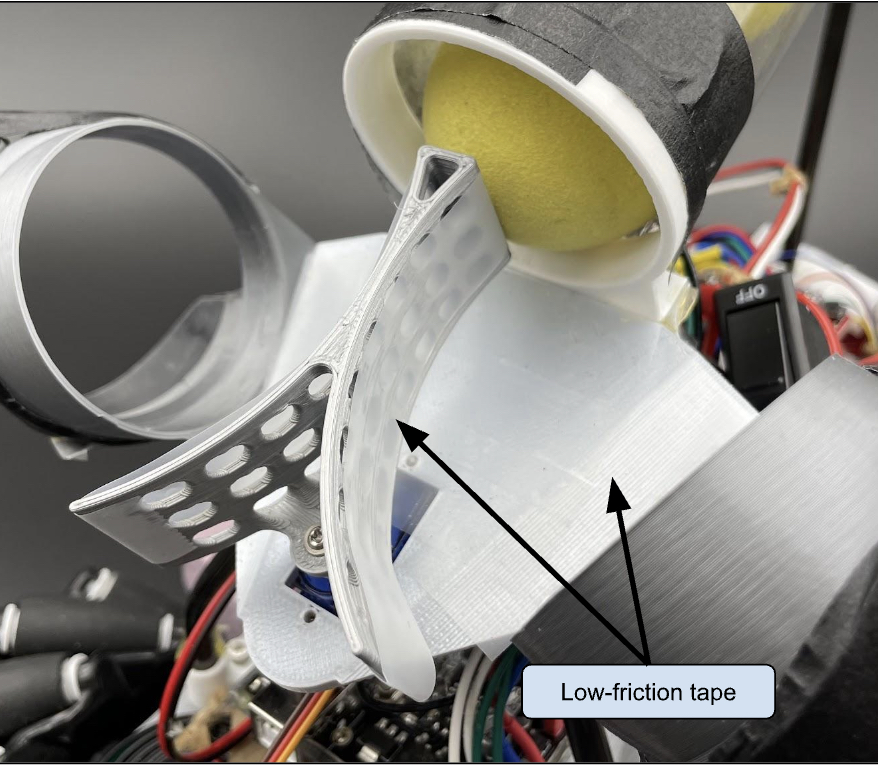

Problem 2: Ball Jamming

The second problem was that the balls would sometimes jam against the selector during deployment. This was attributed to two factors. First, there is a high coefficient of friction between the selector and the ball. This was mitigated by the use of low-friction tape, as seen in the image below.

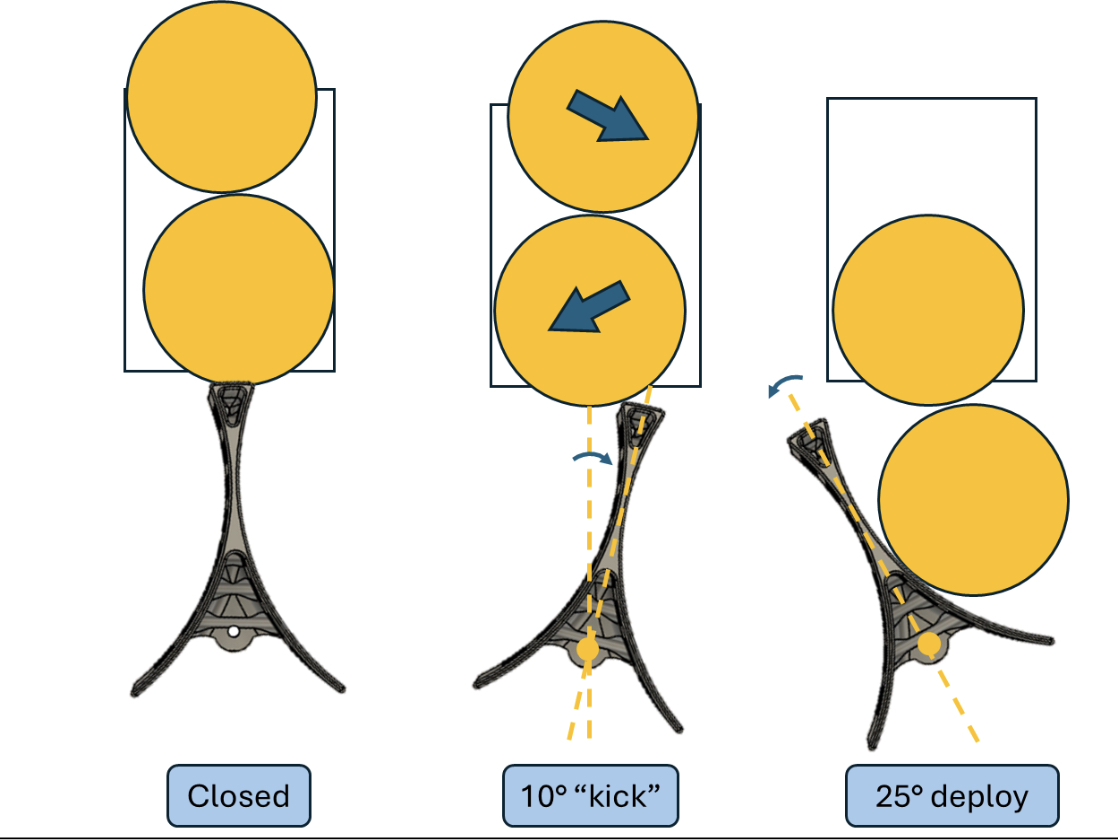

Second, the lateral orientation of the balls in the hopper, which is random based on how they fall while being loaded, could lead to jamming. The solution was to code in a “kick” to one side, prior to rotating into its final deployed position. This “kick” ensured the balls were oriented properly before the selector was positioned for deployment. The sequence can be seen in the image below.

This realignment sequence did help with deployment consistency, and we were able to obtain a >90% deployment reliability. However, challenges with code implementation meant that we were not able to fully overcome the geometric problems with our design.

On reflection, we could have refined the relative positioning of the hopper and deployment tubes to eliminate the need for the “kick”. By increasing the distance between the hopper and deployment tubes, the diameter for the tangent circle connecting the tubes would have increased, improving the angle of incidence of the balls on the selector, and reducing energy losses due to impact and friction. However, overall, the payload delivery system proved adequately reliable, fast to offload (under 2 seconds), and incredibly fast to reload (<1 second).